Flange telescopic butterfly valve

Flange telescopic butterfly valve

Nominal diameter: DN50 ~ 2000 (mm)

Nominal pressure: PN0.6 ~ 1.6 (MPa),

Applicable temperature: X: -40 ℃ ~ 90 ℃; XF: -20 ℃ ~ 200 ℃ (soft seal) ; Carbon: -29 ℃ ~ 425 ℃ stainless -40 ℃ ~ 650 ℃ (hard seal)

suitable medium: water, air, natural gas, oil and weak corrosive fluid

drive: worm gear, electric, pneumatic, hydraulic

valve Body material: WCB, QT450-10, stainless steel

Product Description:

Flange telescopic butterfly valve with automatic compensation pipeline thermal expansion and contraction convenient loading and unloading function, used in the temperature below 120 ℃, nominal pressure below 1.6MPa in the oil, chemical, power, paper, water supply and drainage and municipal construction and other industrial pipe The optimal device for regulating flow and carrying fluid.

Working principle:

Flange telescopic butterfly valve is divided into three types:

A, ordinary type: optional design according to the expansion of the design specifications installation, if you need to limit the bolt, please specify when designed.

B, fixed limit type: it can be telescopic, but also limit, with the telescopic part of the fixed up and not let the expansion and contraction of the function. It is characterized by more features, wider scope of application.

C, lengthened: it is the ordinary type of telescopic butterfly valve expansion section, so that the length of the user to meet the length of the required (not including the amount of expansion and contraction), which is characterized by the transformation of the old pipeline, the original pipeline valve needs to be updated Replacement, without the original pipeline on the connection part of the valve lining, can be replaced. Lengthened selection should also be considered when adding limit measures, please specify when the need to limit the design.

Features:

1, the sealing parts can be adjusted to replace, sealing performance and reliable.

2, unique structure, design flexibility, light weight, effort, opening and closing quickly.

3, telescopic butterfly valve can not only compensate for the temperature difference between the thermal expansion and contraction of the function, but also for the maintenance of the valve to facilitate the installation and replacement.

Installation Precautions:

1, flange expansion butterfly valve installation must be flat before, do not random bump, the operation is strictly prohibited to remove the bracket.

2, flange telescopic butterfly valve factory structure length is the minimum length, installation, pull to the installation length (ie design length).

3, when the length between the pipeline longer than the expansion valve installation length, please adjust the pipe spacing, do not force the expansion of butterfly valve, so as not to damage the butterfly valve.

4, flange telescopic butterfly valve can be installed in any installation, do the temperature compensation, when the pipeline is installed, the direction along the pipeline at both ends of the bracket, to prevent telescopic valve telescopic tube pulled out.

The main technical parameters:

Nominal diameter DN (mm) | 50 ~ 2000 | 50 ~ 1600 | ||

Nominal pressure PN (MPa) | 0.6 | 1.0 | 1.6 | |

Seal test (MPa) | 0.66 | 1.1 | 1.76 | |

Strength test (MPa) | 0.9 | 1.5 | 2.4 | |

proper temperature | Soft seal | X: -40 ° C to 90 ° C; XF: -20 ° C to 200 ° C | ||

Hard seal | Carbon steel: -29 ℃ ~ 425 ℃ stainless steel -40 ℃ ~ 650 ℃ | |||

Applicable media | Water, air, natural gas, oil and weakly corrosive fluids | |||

Leakage rate | Meet the GB / T13927-92 standard | |||

Drive mode | Worm gear, electric, pneumatic, hydraulic | |||

Main parts materials:

Part Name | material |

Body | WCB, QT450-10, stainless steel |

Butterfly board | WCB, QT450-10, stainless steel |

Valve shaft | 2Cr13 stainless steel |

Sealing ring | rubber |

filler | Flexible graphite |

Adoption of standards:

Manufacturing standards | JB / T8527-97, GB / T 122387-89 |

Flange standard | GB9113-2000, GB17241.6-1998 |

Inspection standards | GB / T 13927-92 |

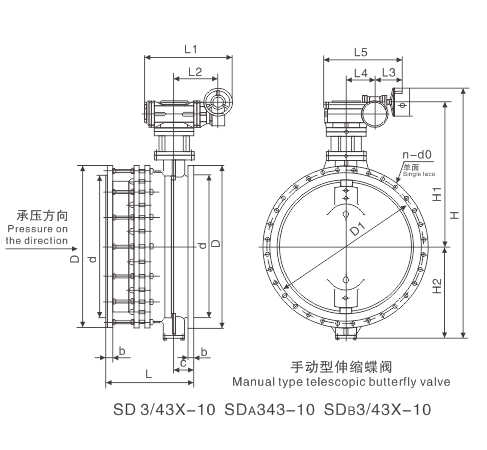

| DN (mm) | Manual device | D | D1 | d | b | C | L | n-d0 | 4-M | H | H1 | H2 | L1 | L2 | L3 | L4 | L5 | φ | WT (kg) | ||

| L0 | Lmax | Lmin | |||||||||||||||||||

| 300 | 3D-30/250 | 445 | 400 | 370 | 28 | 57 | 282 | 302 | 252 | 8-φ23 | M27 | 959 | 542 | 267 | 449 | 178 | 254 | 104 | 473 | 300 | 148 |

| 350 | 3D-30/250 | 505 | 460 | 429 | 30 | 64 | 301 | 321 | 271 | 12-φ23 | M20 | 1048 | 583 | 315 | 449 | 178 | 254 | 104 | 473 | 300 | 188 |

| 400 | 3D-30/250 | 565 | 515 | 480 | 32 | 70 | 313 | 333 | 283 | 12-φ28 | M24 | 1120 | 620 | 350 | 449 | 178 | 254 | 104 | 473 | 300 | 237 |

| 450 | 3D-30/250 | 615 | 565 | 530 | 32 | 76 | 334 | 354 | 304 | 16-φ28 | M24 | 1190 | 667 | 373 | 449 | 178 | 254 | 104 | 473 | 300 | 268 |

| 500 | 3D-30/400 | 670 | 620 | 582 | 34 | 76 | 346 | 366 | 316 | 16-φ28 | M24 | 1280 | 702 | 428 | 486 | 178 | 254 | 130 | 528 | 300 | 289 |

| 600 | 3D-60/800 | 780 | 725 | 682 | 36 | 89 | 398 | 418 | 368 | 16-φ31 | M27 | 1409 | 759 | 450 | 627 | 196 | 245 | 162 | 596 | 400 | 480 |

| 700 | 3D-60/800 | 895 | 840 | 794 | 40 | 115 | 425 | 445 | 395 | 20-φ31 | M27 | 1613 | 885 | 528 | 627 | 244 | 245 | 162 | 596 | 400 | 645 |

| 800 | 3D-120 // 1500 | 1015 | 950 | 901 | 44 | 120 | 455 | 475 | 425 | 20-φ34 | M30 | 1736 | 1013 | 573 | 635 | 244 | 295 | 196 | 711 | 300 | 818 |

| 900 | 3D-120 // 1500 | 1115 | 1050 | 1001 | 46 | 120 | 485 | 505 | 455 | 24-φ34 | M30 | 1860 | 1071 | 639 | 635 | 270 | 295 | 196 | 711 | 300 | 956 |

| 1000 | 3D-120 // 1500 | 1230 | 1160 | 1112 | 50 | 150 | 495 | 515 | 465 | 24-φ37 | M33 | 2107 | 1234 | 723 | 955 | 270 | 296 | 295 | 807 | 300 | 1277 |

| 1200 | 3D-120 // 1500 | 1455 | 1380 | 1328 | 56 | 175 | 542 | 562 | 512 | 28-φ40 | M366 | 2326 | 1343 | 833 | 955 | 455 | 296 | 295 | 807 | 300 | 1764 |

| 1400 | 3D-200/4000 | 1675 | 1590 | 1530 | 62 | 195 | 612 | 632 | 582 | 32-φ43 | M39 | 2996 | 1668 | 1078 | 1270 | 455 | 387 | 414 | 1089 | 500 | 4280 |

| 1600 | 3D-200/4000 | 1915 | 1820 | 1750 | 68 | 220 | 640 | 660 | 610 | 36-φ49 | M45 | 3246 | 1778 | 1218 | 1270 | 598 | 387 | 414 | 1089 | 500 | 4953 |

| 1800 | 3D-200/12000 | 2115 | 2020 | 1950 | 70 | 245 | 710 | 730 | 680 | 40-φ49 | M45 | 3720 | 2044 | 1426 | 1628 | 745 | 387 | 602 | 1399 | 500 | 7416 |

| 2000 | 3D-600/12000 | 2325 | 2230 | 2150 | 74 | 270 | 775 | 795 | 745 | 44-φ49 | M45 | 3851 | 2115 | 1486 | 1630 | 750 | 417 | 602 | 1399 | 500 | 9372 |

Zhejiang public security reserve No. 33032402001552

Zhejiang public security reserve No. 33032402001552